Cathodi-Clamp Models

Laser Welding & Water Jet Rates Available Upon Request

info@hwy83mfgnd.com

Solve Corrosion Problems by Using the Cathodi-Clamp

The Cathodi-Clamp® is used to attach sacrificial anodes to buried iron water mains:

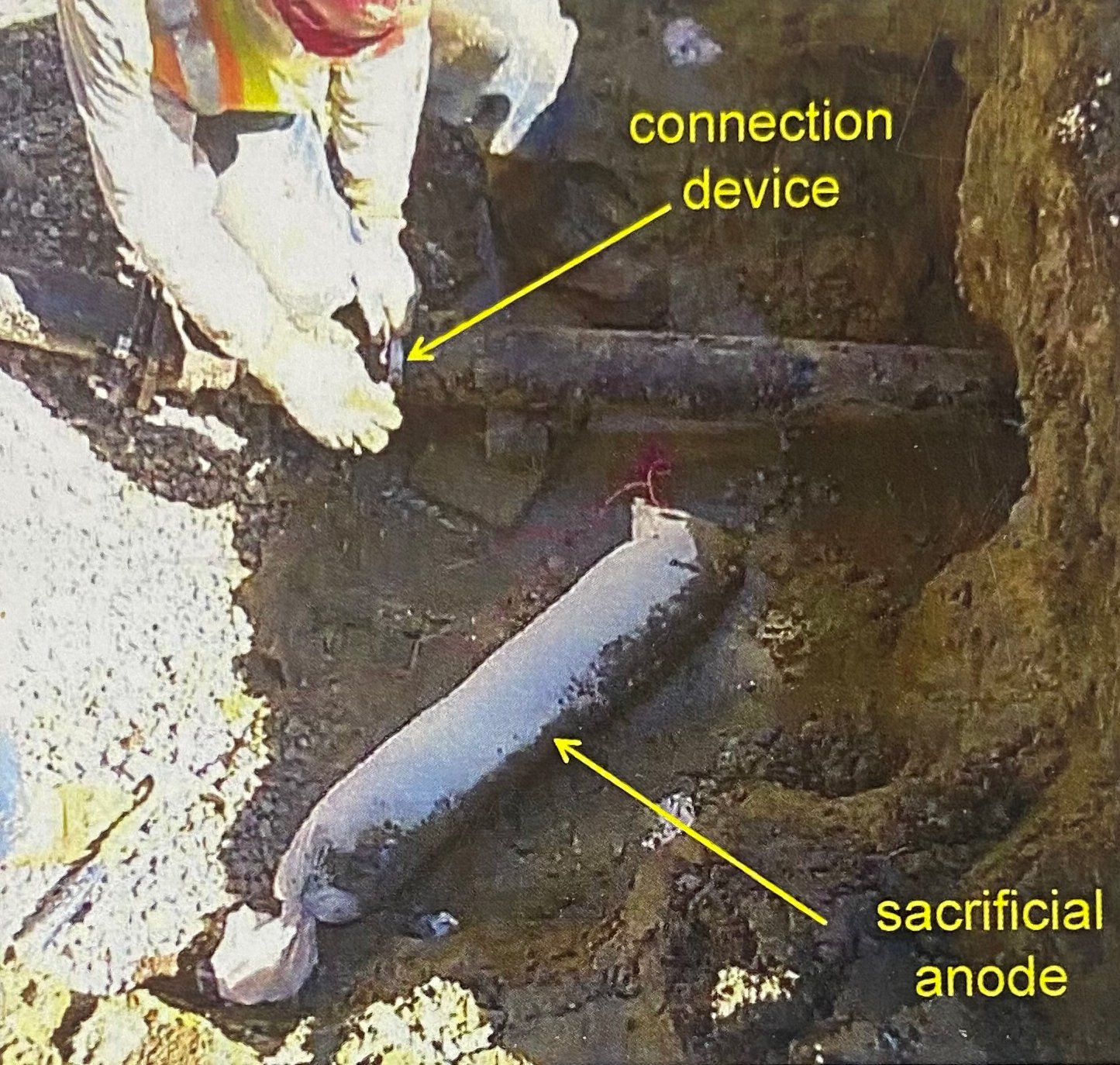

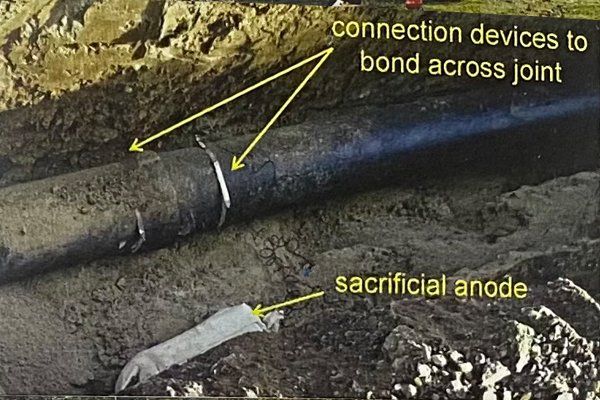

- Connects sacrificial anodes to buried water main piping using just simple hand tools

- Eliminates personnel safety hazards versus thermite welded connections in wet excavations

- Proprietary “cutter bolt” minimizes pipe surface preparation

- Proprietary silver-soldered lead wire connection ensures electrical conductivity

- Available in four sizes to fit iron water main pipe up to 24 inches in diameter and as small as 3.5 inches.

We supply cathodic clamps and sacrificial anode bags to the North American Water Industry. We are a local and family-owned company since 1989.

Contact Hwy 83 Manufacturing for more information.

What's Your biggest Cost to Repair a Main Break?

Use a Secure Connection to Bond Across Pipe Joints

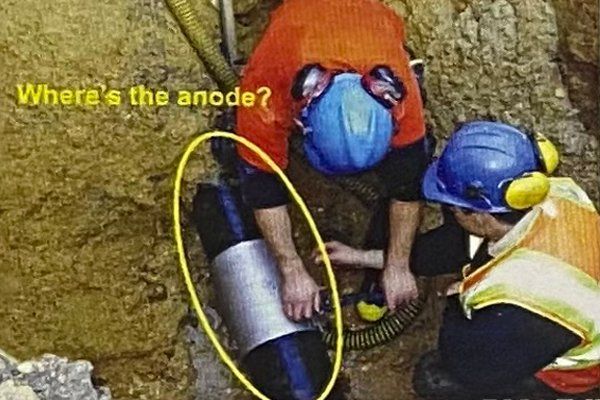

Hot-Spotting: CP Anodes at Water Main Break

Use a Secure Connection to Attach Sacrificial Anodes

Safe Work Practice in Wet Trench Conditions

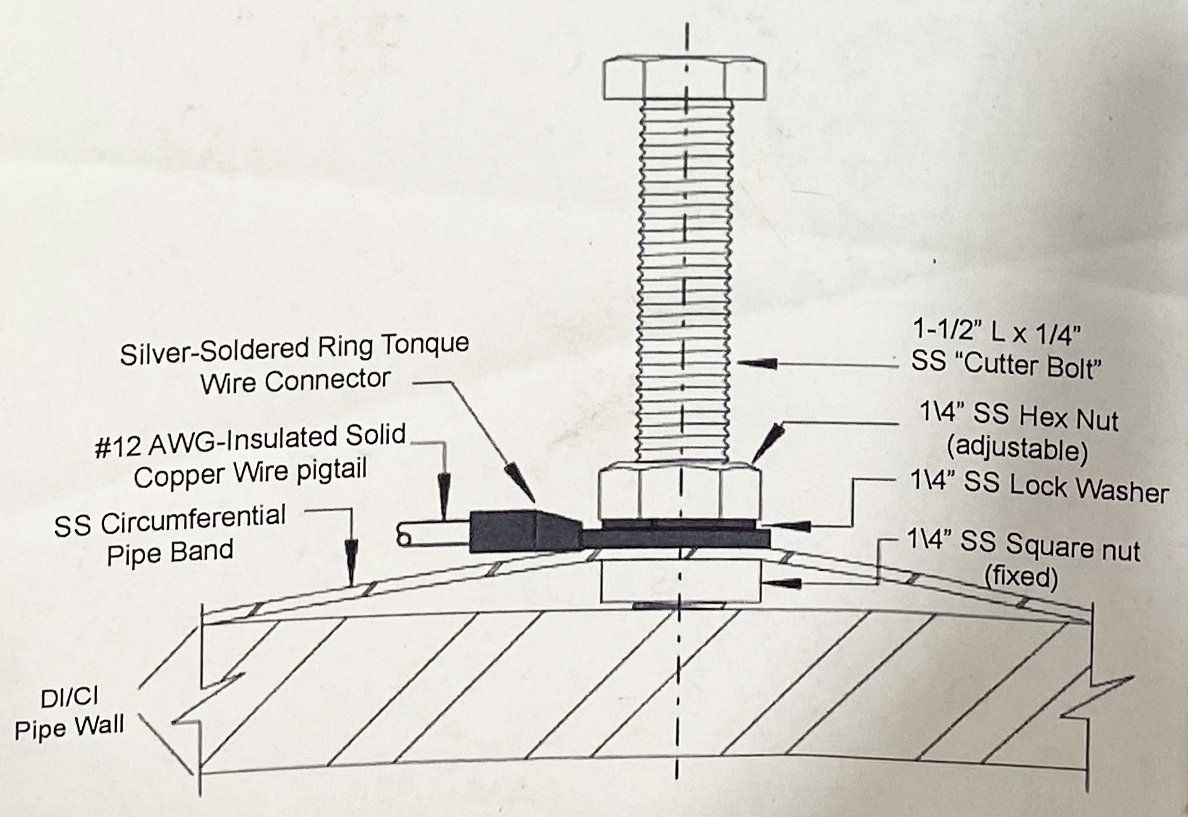

The Cathodi-Clamp® is an Engineered Connection Device

AWWARF Shows that CP Reduces Main Breaks

- Document all leak and main break repairs as recommended by AwwaRF

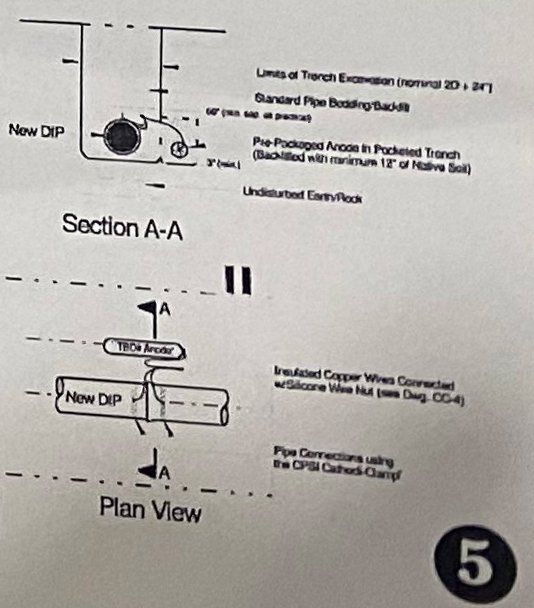

- Install a sacrificial anode every time the main is exposed for repairs or tapping

- Install the anodes where earlier leak problems have occurred

Beware of Inferior Products – Weak Connection Point

Cathodic Protection is Proactively Inexpensive

Cost of repairing a water main break versus installing a sacrificial anode during a pipe repair...

- Average Cost of a Main Break - $3,500 to $7,000 (or more*)

- Cost of a CP Anode and a Connection Device - Less than $175!

Solving Corrosion Problems Using the Cathodi-Clamp® for Water Main Breaks

Cathodi-Clamp

Available in four sizes to fit iron water main pipe up to 24 inches in diameter and as small as 3.5 inches.

- 6” to 8” pipe sizes

- 10” to 12" pipe sizes

- 12" to 16” pipe sizes

- 18” to 24” pipe sizes

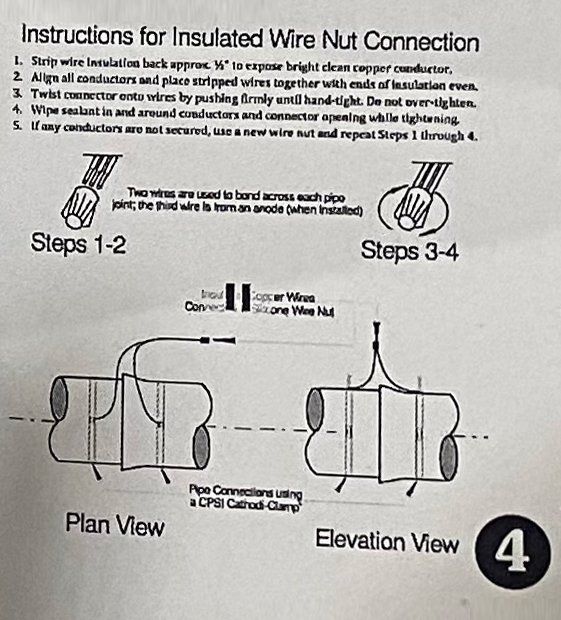

Cathodi-Clamp® Connection Device Installation Instructions for CI/DI Water Mains

- Wrap the stainless steel (SS) band around the exterior of the pipe with wire pigtail and the hex cap "cutter” bolt near the top of the pipe.

- Insert the free end of the SS band into the band "buckle" making sure that the band/square nut are both resting completely flat against the pipe surface.

- The exposed end of the 1/4” cutter bolt should extend no more than 1/8" beyond the face of the square nut toward the pipe's surface.

- Pull on the free end of the SS band to place it in tension around the exterior of the pipe.

- Bend the free end of the SS band back against the inside edge of the buckle to hold the band securely to pipe.

- Strike the fastener “wings" of the buckle with a hammer (or similar blunt object) to hold the free end of the buckle in place. The excess length of free end of the SS band may remain in place or may be removed.

- Slightly loosen the adjusting hex nut on top of the SS band.

- Using a socket/open/box-end wrench, slowly tighten the SS hex “cutter” bolt to draw the SS band tight against the pipe and to ensure that the bolt "bites" into the exposed pipe surface. Although a torque-wrench is not required, this effort will be between 100 and 125 inch-pounds applied at the "cutter bolt” head.

- Tighten the adjusting SS hex nut on the top of the SS band with an open/box-end wrench.

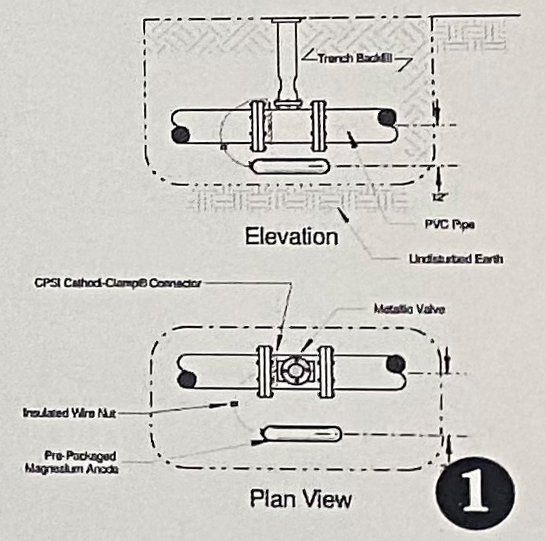

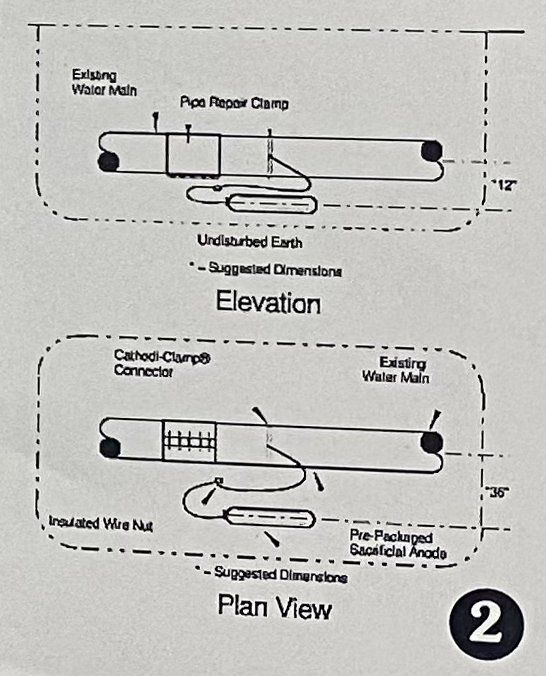

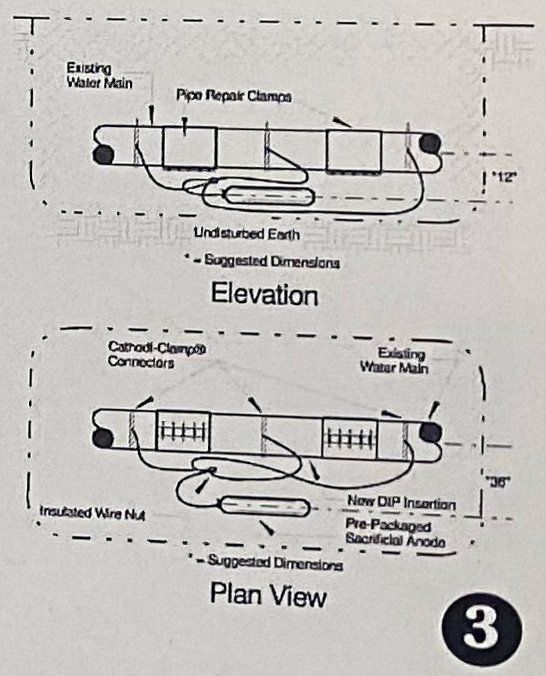

- Your CPSI Cathodi-Clamp® connection is now completed! You may now connect the 5' wire pigtail directly to a sacrificial anode using an insulated wire nut. Refer to CPSI Drawing #CC-1 (Metallic Valve), #CC-2 (Single Break Repair Clamp). and #CC-3 (Multiple Break Repair Clamps) for typical Cathodi-Clamp® installation details.

Share On: